Not All Tributyrins Are Equal

The benefits of including a tributyrin product in feed formulations is widely accepted, but not all tributyrin products, or their suppliers, are the same. Here are seven key factors to consider before making your next tributyrin purchase.

The benefits of butyric acid

Butyric acid has shown many benefits when used in animal nutrition including:

• improving absorption of nutrients

• supporting animal performance

• supporting gut health

• maintaining high standards of animal wellbeing

Delivering butyric acid to the lower part of the intestine can be challenging as it is rapidly absorbed in the upper gastrointestinal tract. It is a liquid that has a pungent smell and a bitter taste, so how can this useful feed additive be included in feed formulations effectively?

Esterification: the chemistry used to deliver butyric acid to the lower gastrointestinal tract

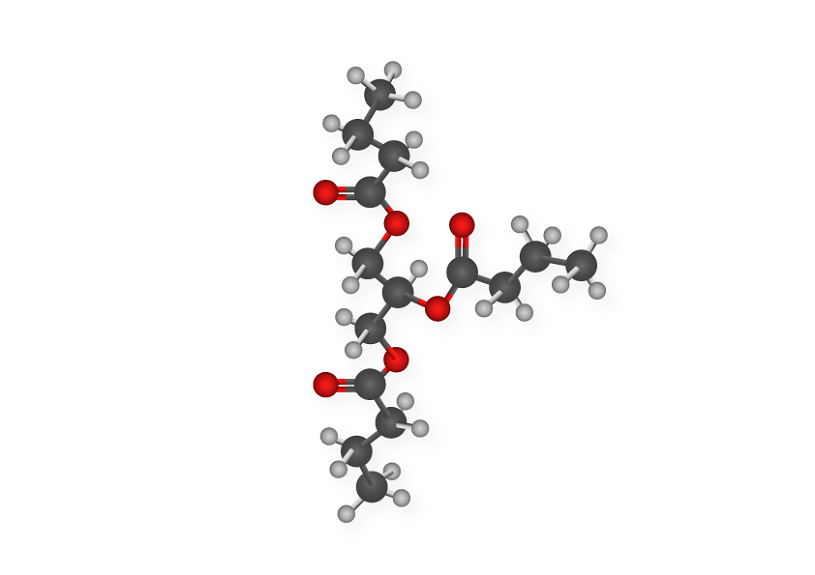

Tributyrins are triglycerides derived from a glycerol molecule and three molecules of butyrate (Figure 1).

Figure 1. Chemical structure of tributyrin

Figure 1. Chemical structure of tributyrinNow that the benefits of tributyrins are commonly accepted, the number of commercially available tributyrin products has increased significantly. Product choice should be based on your unique set of criteria. Various factors should be considered; price – or better, return on investment – is one of them. However, the cheapest product might not be the best choice for you and your bottom line. Making sure you choose the product and supplier that can best meet your total needs is vital.

Here are seven other factors to consider before making your tributyrin product choice, each with a practical tip to simplify the decision-making process.

1. Product quality and certification

Using high-quality ingredients is essential to guarantee a final product quality that is free from impurities. Are feed grade materials used to create the product? Even though laws differ between countries, all products should be safe for use in feed and food chains.

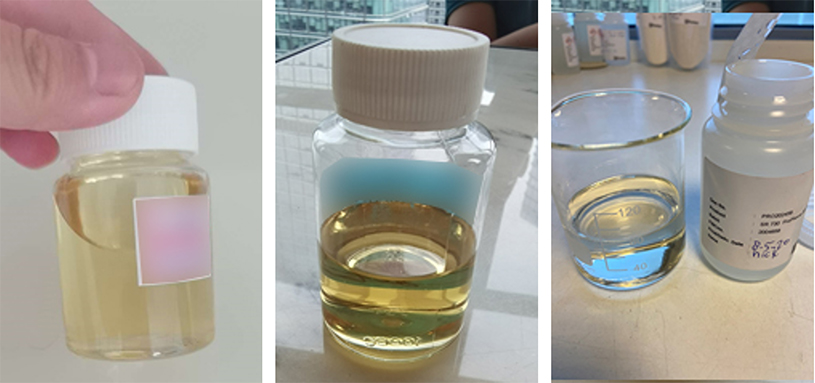

Figure 2. Samples of various tributyrin products. ProPhorce™ SR is the sample on the right.

Figure 2. Samples of various tributyrin products. ProPhorce™ SR is the sample on the right.

Figure 2 shows different samples of tributyrins. It is clear they are not all equal. Colors can vary a lot. The picture on the right is ProPhorce™ SR.

Butyric acid is known for its pungent smell. This smell will be detected even if a very low percentage has not been esterified. The final product should not have a smell. Anyone working with or around the product in the feed mill will immediately tell if the tributyrin product is unstable and losing concentration.

2. Product concentration and consistency

One key factor to look for when purchasing a tributyrin product is the percentage of active butyric acid. But the concentrations of liquid and dry products, and those from different vendors and can be very different so compare similar products to make a fair assessment.

Product concentration will vary between batches but a consistent production process using high quality raw materials will reduce variability. Check the concentration range given by the supplier, and whether they make regular checks to ensure the concentration of the product is within that range.

If product concentration is highly variable between batches, this will cause problems when formulating the feed. Minimizing variation in product concentration will help the nutritionist; any feed additive included in the diet should not complicate the already delicate process of feed formulation.

The high-quality production processes used by Perstorp means that the concentration of ProPhorce™ SR tributyrins is among the highest of all the commercially available tributyrin products. This means the same or better performance results are achieved with lower dose rates, in some cases when only half of the dose of a coated butyric acid product is used.

TIP: Look for a supplier with their own laboratory who carry out quality checks on every batch before shipping.

3. Stability

Good storage stability is essential. In some products, the concentration of tributyrin shifts to di- or mono-butyrin after 6 months. This drop in product concentration may result in variable performance.

As well as being stable, the product must also be able to withstand the processes used in commercial animal feed manufacturing These processes typically include periods of high temperature which might cause the product to destabilize, resulting in smell issues or unwanted reactions with other components of the feed.

TIP: Check the stability data available for the product. A stable product is more likely to reach the target area of the gastrointestinal tract.

4. Shelf life

Shelf life is another important factor to consider. Unstable products will deteriorate over time. The esters will hydrolyze, reducing the concentration of tributyrin.

Table 1 shows the results of a stability trial for three samples of ProPhorce™ SR. The recovery tests show negligible product loss after 24 months of storage.

|

Batch |

Tributyrin (TBU) |

|

|

Day 0 |

After 24 months |

|

|

1 |

100% |

98.7% |

|

2 |

100% |

100.1% |

|

3 |

100% |

100.3% |

Table 1. Storage stability of three samples of ProPhorce™ SR over 24 months. The original measurement is 100%.

TIP: A long shelf life is an indicator of a stable product.

5. Flowability

Dry tributyrin products should flow easily. The carrier used for dry tributyrin products makes a huge difference; it should have high levels of dispersion and should not cake at all. Creating a non-caking carrier product is no easy task but is one that Perstorp has successfully accomplished based on decades of experience in dry organic acid solutions.

Excellent flowability ensures optimal mixing in the feed and reliable dosing, especially at low doses.

TIP: Examine the product with your eyes and your hands. Is it dusty? Does it flow well? If it doesn’t flow through your hand, it won’t mix into your feed consistently.

6. After sales service

Buying a new product that is going to improve your results is exciting, but it is always reassuring to have support from someone who has experience in applying the product to guide you through it. Each feed mill is unique. If any problems arise, you should be able to contact someone to help you identify and solve the problem.

Advice can only be given from a position of experience. Products that have been in the market the longest will have the most amount of data to look at and will have the advantage of application experience in a wide variety of feed mill set ups and diet types.

TIP: How much data is available for the product? How long has it been available on the market? There is a lot to be said for longevity in the highly competitive feed additives market. Good products stand the test of time.

7. Product sourcing and traceability

Control over the whole production process ensures the highest level of product quality, and full traceability on each batch. Dealing directly with a producer of butyric acid has some clear advantages.

TIP: Can the supplier trace each batch of product, including the raw materials?

ProPhorce™ SR – Unrivaled butyric acid power

There are only a few butyric acid suppliers in the world. Perstorp is one of them. And it has now been 10 years since the launch of the original tributyrin product: ProPhorce™ SR. Experience and expertise in the application of tributyrins combined with in-house production facilities gives Perstorp several advantages in the market:

• Control and traceability for each batch of product.

• Raw material quality is closely monitored to ensure the final product is of high purity.

• Variation between batches is minimal resulting in high dosing accuracy and reduced risk for nutritionists.

• Excellent product stability.

• Long shelf life – 24 months

• High thermostability – no significant loss of recovery after heating at 150oC for 5 minutes.

• Excellent flowability with no dust for better product mixing and ease-of-use in the feed mill.

• Experienced and knowledgeable team to support product application.

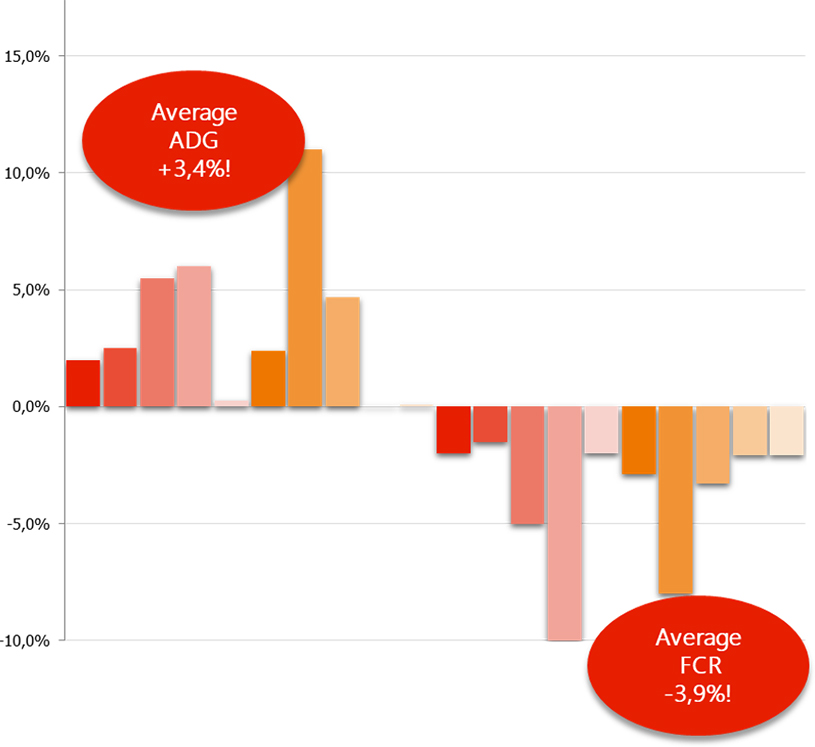

• Over 50 trials run in various animal species that demonstrate product performance. Figure 3 shows an average improvement of 3.4% in terms of average daily gain and an almost 4-point improvement in feed conversion ratio (FCR) when considering all the broiler data captured for ProPhorce™ SR. Similar results have been shown in other species including piglets.

(Source: internal data)

Including a tributyrin product in the feed formulation will support performance results. Make sure the product you choose is stable, high-quality, high concentration and comes with support from an expert application team.