Polyol Ester Based Lubricants: Essential for Sustainable Refrigeration Systems Worldwide

On World Refrigeration Day, we celebrate the vital role that refrigeration systems play in our daily lives. From preserving food and medicine to maintaining comfortable indoor environments, refrigeration has revolutionized our world. However, in the pursuit of sustainable practices, it is crucial to recognize the significance of using high-quality polyol ester (POE) based lubricants in refrigeration systems. These lubricants not only enhance system performance and longevity but also contribute to environmental preservation. In this article, we will explore why POE lubricants are essential to sustainable refrigeration systems across the globe in pursuit of cooling without adding to global warming.

Optimizing System Performance

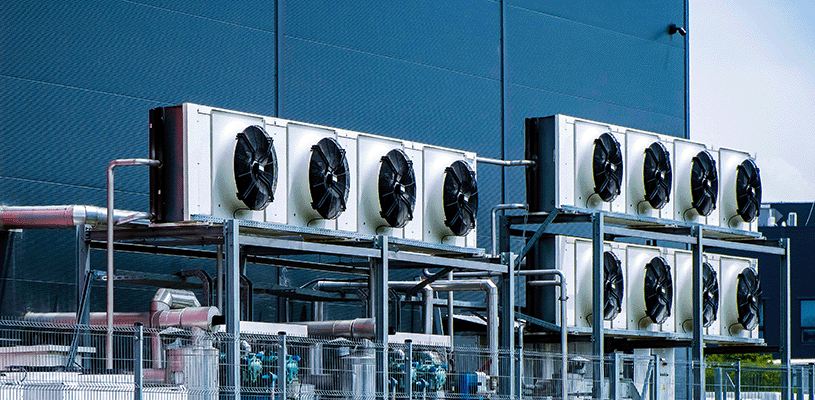

Refrigeration systems consist of various moving components such as compressors, condensers, and evaporators. These components operate under demanding conditions, including high pressures and temperatures. POE based lubricants are specifically designed to withstand such challenging environments, reducing friction and wear between moving parts. By ensuring smooth and efficient operation, these lubricants help optimize the performance of refrigeration systems, leading to energy savings and reduced greenhouse gas emissions.

Extended Equipment Lifespan

The longevity of refrigeration equipment is directly linked to the quality of lubricants used. High-quality lubricants provide superior protection against corrosion, oxidation, and thermal degradation. They also possess excellent viscosity stability, maintaining their lubricating properties over time. By minimizing wear and tear, lubricants help extend the lifespan of refrigeration systems. This translates into reduced waste generation, lower resource consumption, and a more sustainable approach to refrigeration.

Energy Efficiency and Environmental Preservation

Energy efficiency is a critical factor in sustainable refrigeration systems. By utilizing high-quality POE’s in lubricants, friction and mechanical losses within the system are minimized. This leads to reduced energy consumption, lower operating costs, and decreased carbon dioxide emissions. Additionally, lubricants with optimal viscosity reduce the energy required to circulate the fluid throughout the system, enhancing overall efficiency. By adopting sustainable lubrication practices, we can contribute to environmental preservation by reducing our carbon footprint.

Cooling without adding to global warming

As the world transitions to more environmentally friendly refrigerants, it becomes essential to choose lubricants that are compatible with these new alternatives. Many traditional refrigerants have high global warming potential. Polyol ester based refrigeration lubricants are specially formulated for use with more environmentally friendly HFC, HFO and natural refrigerants and is the most common type of synthetic lubricant being used today. POEs can also be engineered from Pro-Environment acids and polyols, thus reducing the industry’s dependency on virgin fossil raw materials and lowering the product carbon footprint of the lubricant itself.

Reduced Maintenance and Downtime

Refrigeration system downtime not only disrupts operations but also adds to the overall environmental impact. By utilizing high-quality lubricants, equipment reliability is enhanced, resulting in reduced maintenance requirements and decreased downtime. The use of lubricants specifically formulated for refrigeration systems minimizes the risk of component failures, leaks, and system breakdowns. This not only contributes to sustainability efforts but also leads to significant cost savings for businesses and individuals alike.

As we mark World Refrigeration Day, it is essential to acknowledge the crucial role that high-quality POE based lubricants play in sustainable refrigeration systems worldwide. The shift toward environmentally friendly air conditioners is accelerating, and demand for refrigeration lubricants that are compatible with the refrigerants used in these air conditioners, is also growing. Perstorp produces 90% of the acid and polyol building blocks used to formulate the ester for a refrigeration lubricant.

With an eye towards the future, we continue to strengthen our capacity to provide the essential sustainable building blocks that can produce low carbon footprint refrigerant lubricants and commit our R&D towards raw materials compatible with next-generation ozone and global warming neutral refrigerants.

Read more about chemical building blocks for a sustainable lubricant industry and why the sustainable journey starts with Perstorp >>