Show

- All

This year we have again seen incremental improvements in many of our environmental measurements; in particular, greenhouse gases and waste per ton of product. This goes hand in hand with us raising the bar. We have set an ambition to become Finite Material Neutral. It is a tough ambition but we have to do it. There is no plan B, because we only have one planet. This will of course over time have an impact on the way we do business and interact within our value chain, which is also when what we do starts to have a real impact.

Our sustainability strategy until now has primarily been based on a strong commitment to operate our business in a resource-efficient way. However, we wanted to take Perstorp’s sustainability leadership to the next level. Significant global challenges lie ahead of us with continued high expectations on the chemical industry.

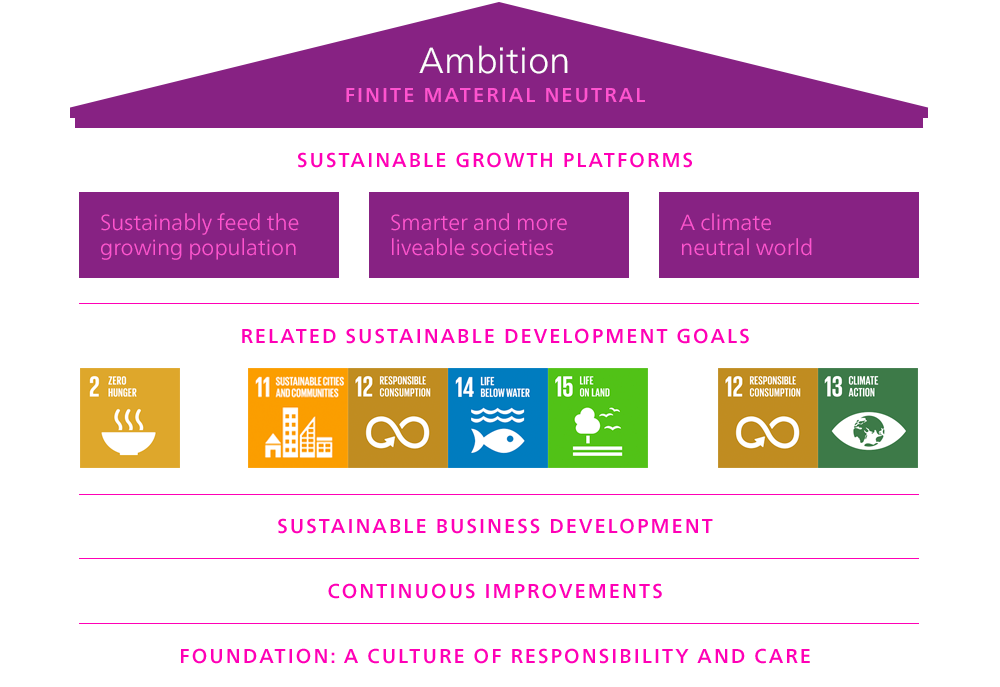

Let me explain a bit more how we are approaching sustainability. Our pathway towards Finite Material Neutral is built on a Strategic Framework consisting of different layers of activities and impact. At the foundation we have placed everything related to running a responsible business; values, health & safety, compliance, code of conduct etc. The next level is about how we make continuous improvements to our products and work with our Sustainability Index, in order to map out how our products and solutions are positioned from a sustainability perspective. In the area of Sustainable Business Development we work towards contributing to primarily six of the UN Sustainable Development Goals. This is driven by three sustainable growth platforms; Sustainably feed the growing population; Smarter and more livable societies; and a Climate neutral world. One of our focus areas is to replace fossil raw materials with renewable or recycled raw materials which is important to reach our long term ambition to become Finite Material Neutral.

Becoming Final Material Neutral to us means to switch from fossil resources to renewable, recycled or reused, supporting circular economy. This shift will not happen overnight and we are humble about our ambition. But it needs to be done and here we find great support in our core values;

Responsibility

Reliability

Focused innovation

Perstorp also has an opportunity to further develop its pro-active contribution to sustainability through products, solutions and knowledge. Imagine the positive impact we can have through our products that reduce food waste, reduce use of anti-biotics in feedstocks or make durable products last even longer or use less resources.

This year we also started up a new social initiative by partnering with the Hunger Project, which funds local investments to support women in especially poor societies. This new way of contributing to society will become important for us in order to live up to our commitment to be a responsible corporate citizen, in areas that matter.

We believe we can make a substantial contribution to Agenda 2030 and the UN Sustainable Development Goals (SDGs) as part of our efforts. As a company with strong fundamental values, and as a proud signatory of the UN Global Compact, we will also continue to support the development of a global agenda for a more sustainable world.

Malmö, April 2018

Jan Secher

President and CEO

This is the Perstorp Group’s statutory sustainability report for the fiscal year 2017. It was prepared in accordance with the requirements of the Swedish Annual Accounts Act, and includes our reporting on environmental issues, employee and social matters, human rights and anti-corruption. This report covers all subsidiaries of the Perstorp Group.

In addition, in the Perstorp Group Annual Report, pages 8-9 there is reporting on the Group’s most material risks, of which some are related to these issues.

The sustainability report has, together with the Annual Report, been submitted by the Perstorp Group’s board of directors.

Perstorp are signatories to the UN Global Compact and the sustainability report thus constitutes the Group's annual Communication on Progress. No other guidelines have been used in the preparation of this report.

The Perstorp Group is a world leader in several sectors of the specialty chemicals market for a wide variety of industries and applications. Our products are added to a wide range of products used every day at home, work or leisure. Perstorp believes in improving everyday life – making it safer, more convenient, and more environmentally sound for millions of people all over the world. As a trusted world industrial leader, our innovations provide essential properties for products used every day at home and work. You’ll find us everywhere from your car and mobile phone to towering wind turbines and the local dairy farm. Simply put, we work to make good products even better. Perstorp’s focused innovation builds on more than 135 years of experience, representing a complete chain of solutions in organic chemistry, process technology and application development. Manufacturing is based in Asia, Europe and North America, with sales and support in all major markets. The Perstorp Group is controlled by funds managed and advised by the European private equity company PAI partners.

In recent years, there have been a focus on renewable raw materials. Thinking in a sustainable way is part of our future, but it also takes us back to our roots. We started by utilizing local, natural resources from the heavily wooded region of southern Sweden to produce what we, today, call second-generation bio-based chemicals and fuels. So there is really a retro-chemistry aspect integrated into sustainable chemistry.

From the very beginning, we have been a pioneer in renewable raw materials for chemicals. Since then, we have continued to take an active lead in finding new ways to gain advantage from sustainability in different parts of our business. Last year, we announced the world’s first renewable and ISCC certified portfolio for the essential polyols Penta, TMP and Neo. By switching to renewable alternatives, we can reduce carbon footprint by up to 80%.

In 2010, Perstorp along with the four other international chemical companies in Stenungsund, Sweden, developed the Sustainable Chemistry 2030 vision for a sustainable society. This group of companies has a vision to form a center for sustainable products with production based on renewable and recycled raw materials and energy.

The Sustainable Chemistry 2030 vision includes the aim for organic molecules like ethylene, propylene, and natural gas to be derived from renewable and recycled sources such as bio-feedstock and recycled plastics. In doing so, we can help significantly reduce the industry’s dependence on fossil oil and gas, or even removed altogether. This can often be achieved without affecting either the chemical processes in the factories or the quality of the end products.

In the last few years we have seen an increased awareness of the benefits of sustainable chemistry, resulting in a steady growth in market demand. Discussions with key customers have also shown that sustainability is of increasing importance. Key product requirements now also include renewable raw materials and low carbon footprint products.

In addition to replacing fossil-based raw materials, the overall sustainability and environmental impact of a customer’s end-product is becoming key. For us, that means we are also looking at product end-of-life (biodegradability and recyclability) and improving the sustainability of the basic building blocks and feedstock elements. It also means enabling more sustainable end-product properties like lead-free PVC, next-generation plasticizer, bioplastics, waterborne alkyd resins and reducing the level of VOCs released as the coating dries.

When it comes to "becoming green" in the chemical industry, it is a big focus on being renewable and sustainable, two cornerstones of our commitment to the industry and a core focus within our company. And while other companies may talk big about sustainability, for over 100 years we have been letting our actions speak for us and our ongoing and active commitment to sustainable chemistry.

Sustainability has always been close to our hearts at Perstorp. It’s with us in the strategic decisions we take and in the little, everyday tasks. Our direction is clear. We have the ambition to be Finite Material Neutral. Finite materials are resources that cannot be created or produced once the original stores are depleted, or those that are used up at a greater rate than nature can replenish. Becoming Final Material Neutral would mean switching to alternative resources that are abundant and/or renewable, or to close the loops to recycle or reuse finite resources. It will not happen overnight, and we are humble about our target, but it needs to be done. Because we’ve only got one planet. To reach our ambition we have identified a number of areas that we will focus on.

We are committed to eliminating or reducing waste in all phases of the value chain. This includes solids, liquids and vapors from our suppliers’ manufacturing, losses in transportation and storage, our own internally generated wastes, and those of our customers and their customers – all the way to our products' end-of-life. We firmly believe that waste is a failure of imagination. Waste is simply a product that has not found its market.

All our operations, and those of our suppliers and customers, emit chemicals and pollutants into the atmosphere and water. It is our duty to reduce these emissions. Our task is to move closer and closer to zero emissions to reach our goal of Finite Material Neutral.

The use and discharge of water is of growing concern around the globe, and Perstorp is already taking steps to conserve and re-use water in all our manufacturing plants. As we design new products, we strive to always take the use and re-use of water into account.

We are in the process of shifting our energy sources to cleaner, more renewable ones. Today, we produce steam at some of our plants, which helps heat the local community. In the future, we aim to become fossil-energy neutral, and possibly green-energy positive, offering our excess energy to people who live in the areas where we operate.

Today, our raw materials are predominantly derived from fossil sources such as petroleum and natural gas. We have been looking at developing renewable raw materials both internally and in collaborations for many years, and we are now identifying and sourcing an increasing amount of renewable materials. Metal Catalysts are being reclaimed, and new processes that use more plentiful or even no catalysts will be employed in the future.

As Perstorp matures regarding sustainability, we continually build our knowledge base and make new connections and partnerships. The journey towards our ambition to be Finite Material Neutral, we cannot achieve without collaborating along the value chain in new ways. We ally ourselves with like-minded companies, trade groups, institutes and individuals to push technology forward. A deeper understanding of our stakeholders' needs and priorities is at the heart of our journey.

We have to live as we learn to reach our ambition. All the focus areas listed here contain elements of our ambition to become Finite Material Neutral, and along the way we should act as role models in the various aspects of how we behave. It’s in the individual footprints we leave behind; e g in how much we fly, what we eat, how much we consume, and what we recycle. We want to reduce our environmental impact as much as possible, and if each of us makes an effort, together we can make an impact. Every single effort – small or big – matters.

Our ambition - Finite Material Neutral

We’ve only got one planet. We get no second chances, so we’d better look after it. Building a more sustainable world is all of our responsibility. It may seem daunting but just take it one step at a time. And if a billion people can take a billion first steps we can change our world – for the better. Perstorp has taken many steps down the pro-environmental path, and declare we are proud pro-environmentalists. Sustainability has always been close to our hearts and in 2017 we launched world’s first renewable portfolio of the essential polyols Penta, TMP and Neo which we talk more about below. During 2017 we raised our bar. We have now also set a clear direction in our ambition to become Finite Material Neutral. It will be a challenge but we are committed and we are convinced we can make it.

Renewable and ISCC certified Polyols

During 2017 Perstorp announced that all three essential polyols - Penta, TMP & Neo - now come in renewable grades. With these products, we are supporting the circular economy and the shift towards raw material derived from renewables and waste sources. For example, instead of using fossil natural gas as a raw material for Evyron™ and Neeture™ we are using biogas produced locally from waste.

In 2010 we were the first company in the world to launch a renewable Penta called Voxtar™. Today it comes in 40% and 100% renewable grades, and can reduce the carbon footprint by 60-80%. Evyron™ and Neeture™ come in partly renewable grades, 20-50%, and reduce the carbon footprint by 40-60%. All our pro-environment polyols – Evyron™, Neeture™, Voxtar™ – are certified by third-party ISCC and come with a Proof of Sustainability which confirms your contribution to sustainable sourcing according to a mass balance system.

Mass balance concept

Mass balance is an ingenious concept that allows our customers and us to switch to renewable raw material in easy steps. We believe mass balance is a necessary strategy for industry to switch from fossil to renewable and recycled resources. We have to take it stepwise as building wasteful, parallel systems would neither benefit the environment nor the economy. Mass balance is about mixing fossil and renewable but keeping track of their quantities and allocating them to specific products. The actual carbon molecules in the product may not be renewable, but through a third-party certificate, the renewable content is verified. This helps us all support sustainable sourcing of renewable raw material and see the actual savings in CO2 emissions. Eventually, all the raw materials will be from renewable sources and every molecule you receive in the future will be from a sustainable source.

Using waste liquid as raw material

During 2017 we invested in our Penta plant in Toledo which allows us to purify and utilize the waste liquid from the Penta production and re-use as a raw material. Instead of being sent for treatment, the waste stream has found a new purpose. With the added investment, we are dramatically decreasing the amount of chemicals sent from this plant for disposal. Our intention is to make even further reductions in the near future.

Perstorp is participating in a number of consortia working with sustainable innovation. During 2017 we participated in 11 exploratory projects with 41 external partners, and 9 PhD students at different universities. Here follows three examples:

STEPS stands for Sustainable plastics and transition pathways, and is a project coordinated by Lund University, and financed by MISTRA, which is a research foundation with environmental focus. STEPS is a research program based on input and needs of the industry looking for sustainable solutions from renewable feedstock to post-consumer plastic handling. It involves the rational choice of carbon-neutral building blocks, informed consumers and improved attitudes, as well as favorable policy framework. “STEPS” is focusing on carbon-neutral polyesters, since this is a sizable market, with a wide range of applications, tunable end properties, potential to avoid additives, the inherent ester bond degradability, and reuse of building blocks after plastic end-of life. The program has already delivered the first result, a wooden floor finish – “StepON”, which is a demo product developed already after one year. The consortia involves 10 research groups and 20 stakeholders representing a number of different value chains.

“Cat2BioChem” is a consortium where the synthesis and evaluation of novel polyols and lactones from glucose using isomerization, and retro-aldol reactions are investigated. The goal is the development of low-cost catalytic processes for the production of high-value chemical building blocks and plastics. This involves the development of a platform for the effective discovery, production and upgrading of new chemical produced bio-based building blocks for novel polymer materials with hitherto unknown performance characteristics. “Cat2BioChem” is a collaboration financed by Innovation Fund Denmark, and the partners are DTU, Haldor Topsöe A/S, and Perstorp AB.

Another example is “Depol”, from polyester edge trim to plasticizer through chemical recycling, where we address the following questions: Is it possible to depolymerize polyesters from waste? What is the yield and the composition of the resulting mixture? What is the potential of using the mixture as raw material for the synthesis of plasticizers for PVC? What are the environmental impacts of the process and the resulting products? What are economic and environmental benefits for the interested partners, i.e. JABA group AB, Swerea IVF, Perstorp AB, as well as other stakeholders? The consortia is financed by the Swedish Energy Agency.

Perstorp is a group of companies that develop, manufacture and sell specialty chemicals, which our customers transform into hundreds of products, each with its own unique set of requirements and end uses. We engage in industrial and consumer markets through a variety of channels. Our environmental, social and economic impacts arise mostly from our production facilities and these downstream markets.

Perstorp’s impacts on the wellbeing and economic prosperity of our own employees, associated partners and the communities in which we operate are also significant factors in measuring our success as a corporate steward. In this report, we explore Perstorp’s impacts in detail, consolidated from the eleven production sites (operating in eight countries) which were owned in part or in total by Perstorp at the end of 2017. These sites are:

Perstorp, Sweden

Stenungsund, incl Nol, Sweden

Zibo, China

Bruchhausen, Germany

Waspik, The Netherlands

Fredrikstad, Norway

Castellanza, Italy

Vercelli, Italy

Warrington, United Kingdom

Toledo, United States

In 2017 Perstorp divested one production plant (Gent, Belgium) and acquired another (Vercelli, Italy).

Our performance on the major impacts as listed below showed some improvement in 2017 when compared to the two prior years. Our use of energy per ton of product increased over the prior year, reaching the same level as 2015. Our use of water, emissions of greenhouse gases and waste per ton of product were all decreased. These decreases are a direct result of our continued focus on process efficiency and waste minimization.

| Summary of Impacts | 2015 | 2016 | 2017 |

|---|---|---|---|

| Total Energy (MWh/ton product) | 1.45 | 1.15 | 1.09 |

| Water consumed (liters per kg) | 2.2 | 2.1 | 1.9 * |

| Wastewater COD per ton | 3.8 | 3.6 | 3.3 |

| Scope 1 GHG (kT) | 397 | 379 | 333 |

| Scope 2 GHG (kT) | 98 | 103 | 113 |

| Total GHG (kg/T product) | 314 | 256 | 227 |

| VOC (T) | 187 | 149 | 168 |

| NOx (T) | 160 | 156 | 167 |

| SOx (T) | 5.7 | 8.6 | 8.6 |

| Waste (kg/T product) | 34.2 | 30.7 | 28.8 |

* - excluding site Vercelli, Italy

As our volumes and sales have increased over time, so have our costs related to Responsible Care (RC). The cost to properly dispose of waste has also increased over the past few years in every country where we operate. We continue to invest in the protection of the environment, our employees and other stakeholders at a consistent rate. “Other RC related costs” in the table below includes training costs and certification of local experts.

| Responsible Care (RC) Costs, SEK million | 2015 | 2016 | 2017 |

|---|---|---|---|

| Disposal hazardous waste | 9.3 | 17.4 | 19.8 |

| Disposal of non-hazardous waste | 2.6 | 3.9 | 3.2 |

| Disposal of waste water | 26.4 | 27.1 | 28.7 |

| Contaminated soil | 0.2 | 0.0 | 0.0 |

| RC fees paid | 3.8 | 3.8 | 4.8 |

| RC fines paid | 0.5 | 0.1 | 0.3 |

| Other RC related costs | 33.0 | 32.8 | 34.2 |

| Total RC Costs SEK million | 75.8 | 85.2 | 90.9 |

| % of net sales | 0.7% | 0.8% | 0.7% |

| Total RC investments SEK million | 39.6 | 37.0 | 39.7 |

| % of total investments | 6.0% | 6.7% | 6.1% |

| 2015 | 2016 | 2017 | |

|---|---|---|---|

| Raw Materials (kT) | 2009 | 2436 | 2398 |

| Product manufactured (kT) | 1577 | 1883 | 1964 |

Specialty chemicals manufacturing is in an energy intensive business. Perstorp uses huge amounts of energy at each of its plants, and we continue to use renewable energy in production at our site in Perstorp, Sweden. The experience we have gained from the use of alternative fuels will be a springboard for further use at other sites in the future. Our continued focus on process efficiency has helped us keep our energy consumption low.

| 2015 | 2016 | 2017 | |

|---|---|---|---|

| Energy Produced in-house | 1766 | 1662 | 1549 |

| Renewable energy | 15% | 15% | 16% |

| Reclaimed from production waste | 42% | 59% | 56% |

| Amount delivered externally | (170) | (199) | (195) |

| Energy purchased as steam | 341 | 378 | 447 |

| Renewable energy | 0% | 3% | 6% |

| Electricity from local grid | 331 | 326 | 341 |

| Total Energy Consumed | 2269 | 2168 | 2142 |

| Total Energy (MWh/ton product) | 1.45 | 1.15 | 1.09 |

Essential to human life and societies, drinking-quality water is becoming increasingly scarce. Every one of Perstorp’s plants uses water to some extent; as a solvent for chemical reactions, as a carrier for products or as a heat-transfer medium. We take great care to conserve water, and to return the water we do use back to the environment following careful treatment protocols. Our commitment to the future demands that we use as little water as possible and prevent water pollution through innovative re-uses of our wastes.

Below is a summary of our water use; data from our newly-acquired site Vercelli has been excluded, because it was not collected in a manner congruent with the rest of our sites.

| Water Use (in millions of cubic meters) | 2015 | 2016 | 2017 * |

|---|---|---|---|

| * - without Vercelli | |||

| Surface Water | 17.0 | 17.3 | 18.9 |

| Ground Water | 3.6 | 3.9 | 4.5 |

| Rainwater | 0.02 | 0.01 | 0.02 |

| Municipal Supply | 0.72 | 0.68 | 0.74 |

| Other Sources | 0.37 | 0.45 | 0.50 |

| Total water withdrawn | 21.7 | 22.3 | 24.7 |

| Water returned unchanged | (18.3) | (18.4) | (21.0) |

| Water consumed | 3.4 | 3.9 | 3.7 |

| Water consumed (liters per kg) | 2.2 | 2.1 | 1.9 |

| Wastewater | 2015 | 2016 | 2017 |

|---|---|---|---|

| COD (tons) | 6040 | 6685 | 6534 |

| COD per ton product | 3.8 | 3.6 | 3.3 |

Perstorp has a small continuing use of Ozone Depleting Substances (ODS) in cooling systems across the organization. Those systems use 2.7 tons of ODS coolants, with a leakage of 162 kg in 2017.

Starting in 2016, Perstorp has used certified reference values** for determining our emissions of greenhouse gases (GHG). In 2017 we have compiled more complete data on Scope 2 emissions, leading to a restatement of our Scope 2 and total greenhouse gas emissions for the past three years. We are fortunate to operate plants in Sweden and Norway, where electricity from the grid carries an extremely low CO2 emissions factor.

| Air Emissions | 2015 | 2016 | 2017 |

|---|---|---|---|

| Greenhouse gas (GHG) emissions | |||

| Scope 1 GHG (kT) | 397 | 379 | 333 |

| Scope 2 GHG (kT) | 98 | 103 | 113 |

| Total GHG (kT) | 495 | 482 | 447 |

| GHG (kg/T product) | 314 | 256 | 227 |

| VOC (T) | 187 | 149 | 168 |

| NOx (T) | 160 | 156 | 167 |

| SOx (T) | 5.7 | 8.6 | 8.6 |

** Our references for GHG emissions factors are, in descending order of priority:

United Kingdom Department of Energy and Climate Change 2015 Set of Conversion Factors

United States Environmental Protection Agency 2014 Standard Emission Factors

Ecometrica 2011 Electricity-Specific Emission Factors for Grid Electricity

Intergovernmental Panel on Climate Change 2006 Guidelines for National Greenhouse Gas Inventories

Minimization of waste (in all phases of production) remains a priority at Perstorp. Waste reduction efforts at all our sites, plus the recovery and sale of a former waste stream in Toledo, USA resulted in an overall decrease in waste (per ton of product) in 2017. Also in 2017, about the same amount of waste was incinerated, but much more was able to be used for energy recovery.

| 2015 | 2016 | 2017 | |

|---|---|---|---|

| Hazardous Waste (T) | 42276 | 48601 | 46541 |

| Recycled | 11% | 2% | 1% |

| Incinerated for energy recovery | 73% | 76% | 90% |

| Landfilled | 1% | 0% | 0% |

| Other disposal methods | 15% | 22% | 8% |

| Non-hazardous Waste (T) | 11596 | 9238 | 10027 |

| Recycled | 15% | 14% | 18% |

| Incinerated for energy recovery | 9% | 8% | 11% |

| Landfilled | 60% | 66% | 71% |

| Other disposal methods | 16% | 12% | 0% |

| Total Waste (T) | 53872 | 57839 | 56568 |

| Waste (kg/T product) | 34.2 | 30.7 | 28.8 |

At Perstorp we believe that there is a very strong correlation between the health and safety of our employees and our financial performance. This may sound obvious, but to truly build a culture where everyone puts their own and others safety first requires commitment from all levels. After finding that we had undesirable levels of work-related injuries and health issues, in 2017 we launched our Care 365 initiative. Health and Safety is also now defined as one of our most important growth drives for the whole Perstorp Group.

he work with Care 365 is company-wide initiative and consists of many parts, aiming to improve structures and processes for compliance with occupational health and safety standards. But most importantly it is a matter of creating a culture, through leadership and employee engagement. The goal is to take us to the top quartile of companies in our business category in terms of health and safety performance by 2020. One of the tools we have developed accordingly is the “Perstorp Careway”, our way to interpret where we are in our health and safety maturity based on best practice in the industry.

The essence is that we care about our employees, contractors and neighbors and want Perstorp to be a positive influence on our markets and our world. Today we are placing emphasis on visible leadership from top management, a sense of urgency when it comes to incidents and accidents, clear standards and compliance management.

Improved identification of hazards, increased employee education and an emphasis on risk reduction led to a drop in OSHA-recordable accidents. The drop in lost days can be attributed to one severe injury in 2016, which resulted in over 60 lost days.

Our performance on standard Safety metrics (including our own employees + contractors)

| 2015 | 2016 | 2017 | |

|---|---|---|---|

| Fatalities | 0 | 1 | 0 |

| Lost Time Accidents | 11 | 10 | 8 |

| Total Lost Days | - | 137 | 36 |

| OSHA-Recordable Accidents | 20 | 22 | 16 |

| OSHAR* | 1.1 | 1.2 | 1.0 |

* - (OSHAR = number of injuries x 200 000 / number of hours worked)

Our Code of Conduct forms a recipe by which we live our values. It covers the areas of Perstorp’s business principles, products & sustainability, working conditions and human rights. It has been developed to underline the principles that direct our relations with employees, business parties and other parties. It applies to all companies within Perstorp, for the company’s board, Executive Leadership Team and all employees. Perstorp also expects its suppliers, distributors and other business partners with which it has close relations, to act according to these principles.

Perstorp’s Code of Conduct is based on the company’s three core values and has been developed in accordance with the OECD’s guidelines for multinational enterprises, the chemical industry’s Responsible Care program and the guidelines outlined in the International Labor Organization (ILO) convention. Perstorp supports the UN’s Global Compact and its ten principles as well as the 17 Sustainable Development Goals.

All employees must know the content of the Code of Conduct.

We also have a number of more specific policies addressing anti-corruption, anti-bribery, conflicts of interest and anti-competitive behavior.

In case of any suspicions of illegal conduct or other breaches of our own ethical principles, there is a whistleblowing procedure available on our intranet. But this is seen as a last resorts, as our legal department, the HR department and each manager within the company, is also available for dialogue with our employees, should they need to raise questions regarding interpretations of our policies or wish to raise concerns.

On a quarterly basis all areas of our business are responsible to report into our Legal Risk Review, which is regulated by our Legal Policy. Any litigation, disputes or claims related to legal or regulatory violations that are material to the Group must then be reported. Any investigation by an authority (e.g. police, anti-trust authority) must also be reported.

In 2017 there were no suspected or confirmed cases of corruption, neither through the risk review nor through our whistleblowing procedures.

The legal department has up to now conducted trainings of employees in our policies and procedures. In in 2018 we plan to introduce e-learning modules covering anti-bribery and anti-competitive behavior. This will enable us to better track the implementation of trainings, and also systematically ensure that such trainings are repeated in appropriate intervals, or in case of any updates of policies.

Our Code of Conduct is also addressing risks that can occur in our supply chain. With purchases ranging from bulk raw materials and technical equipment to services and office consumables, we are aware of the risks that somewhere along those supply chains human and labor rights may be violated and operations may cause environmental degradation. We therefore work actively with addressing these risks through our procurement procedures.

Our vendor policy, which we ask our suppliers to act in accordance with, covers issues such as child labor, bonded labor, occupational health and safety and freedom of association. Suppliers are given a risk rating based on country risks. All suppliers of large spend and/or rated as being of specifically high risk, are assessed using our supplier evaluation tool. The tool consists of a number of questions, addressing issues such as human- and labor rights and anti-corruption. The procedure also requires of all the suppliers to acknowledge our vendor policy through signature. 80 % of our spend is covered by this systematic approach. During 2018 we are updating our evaluation criteria and will also look into our risk evaluation criteria, and assess our need to follow-up the suppliers’ self-evaluations with audits. We conduct audits of suppliers already as of today, but then mainly focusing on management systems for quality and environment.

Change within companies, within industries, within sustainability doesn’t really happen on its own. People make it happen. People innovate, improve, push boundaries and enable growth. Each person, each individual, each effort – big or little – makes a difference. Can change everything. That’s why we poured significant effort in 2017 into helping our people develop – clearly and purposefully aligning their individual competencies, goals and tasks with Perstorp’s overarching strategy and vision.

The annual performance review-process (PMD) has dual purposes; first of all it’s about assessing each employee’s performance both when it comes to work results and also behaviors. The other purpose is to make sure the whole organization annually discusses and talks about the Company’s core values, which are broken down into the 10 behaviors in the PMD process. In this discussion each manager gets the opportunity to go deeply into and explain our three Core Values; Responsibility, Reliability and Focused Innovation.

The process also includes development activities, short- and long-term career planning and objectives setting for the upcoming year.

The annual performance review-process is aligned to both the Talent Management Process and the Succession Planning Process (see below).

The Talent Management process is a bi-annual activity to identify, assess and train the next generation of managers. We first ran the process in 2015; in 2017 we had the second group in place. The years in between the two groups are considered to be training and preparation in order to take the next step.

In 2017 we had 21 new individuals (“Talents”) in the program. All of them were identified through the PMD process and then further discussed between the Executive Management Team and the Global HR organization before being offered a place in the program.

The Talent Management assessment measures both the participant’s potential and their readiness to take on new challenges. The assessment also benchmarks our Talents with Talents from other chemical companies and we can see our upcoming leaders coming out very well in that comparison. After the assessment and feedback, everyone gets an individual development plan.

The Talent Management Process is aligned with the Succession Planning Process (see below).

For the second consecutive year we conducted the Succession Planning process throughout the whole global organization.

The process was kicked-off by identifying all critical roles in the organization. Then we determined the essential and successful skills of each role. The next step was to identify short and long term successors for each key role in the company. In this part of the process we aligned the Succession Planning process with the individual Talents. This match gave us input to what we must focus our development activities on going forward.

The Succession Planning Process is used throughout the whole organization and in all different levels in the organization, but is not aligned to the Talent Management Process on local level.

This year we started working with Extra Ordinary Result (EOR) as a methodology to rise above the necessary and achieve the possible. The methodology has helped both the management team and all functions work with their own EOR in order to go for the possible result instead of the necessary. This overarching structure has then been broken all its way through the organization. The plan is to continue using the methodology also in 2018 and to complement it with extended coaching-training to key employees in our organization.

During 2017 we continued with our compulsory Leadership training for all new managers in the Perstorp organization.

We also continued to run the Process Academy. This is a program especially brought forward to strengthen the technology knowledge and network within the company.

During 2017 we decided to make changes to our Employee Survey. Instead of running a big annual survey we shortened it to only 16 questions and decided to measure the result three times during the year. The logic behind this decision was for Perstorp to focus on the areas where we weren’t performing as well as we wanted. Unfortunately there were no big movements in the result in 2017 and we ended up more or less on the same level as the end of 2016.

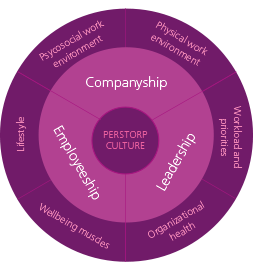

As the Employee Survey (above) shows, workload and stress are on too high a level within the company. Therefore an initiative has been taken to address this issue. Perstorp strongly believes we have to work in three different dimensions in parallel:

Companyship

is about how the company clearly states the expectations in policies, regulations, etc.

Leadership

is about behaviors and prioritization, to help leaders support their employees but also help managers prevent high workload, etc.

Employeeship

is about how the employees can be supported in their day-to-day situation, but also to make clear expectations on their behaviors, etc.

The intensified focus on Health was initiated late 2017 and will be closely aligned to the Safety initiatives during 2018 with a clear ambition to become a top quartile company in health 2020.

We also continued training of all managers within the Swedish organization around Organizational and Social Work Environment. The training is compulsory and aims to provide all managers with knowledge to prevent and handle unhealthy stress and heavy work-load, how to prevent victimization and bullying and how to plan working hours in an efficient way.

Objectives have been set up to improve the Organization and Social Work Environment.

Perstorp is a global company that is open to people of all backgrounds and experiences. We strongly believe that differences makes the company better. By being diverse, we also enhance different perspectives on solutions, supporting better decisions and stimulating higher creativity.

| Men | Women | |

|---|---|---|

| Board members and ELT | 15 (88%) | 2 (12%) |

| PLT * members | 55 (81%) | 13 (19%) |

| Functional Leadership Teams | 44 (80%) | 11 (20%) |

| All employees | 1118 (71%) | 454 (29%) |

In PLT * we have 53 (78%) Swedish citizens and 15 (22%) citizens of other countries.

* PLT is a management forum with employees reporting to ELT or being members in one of the Functional Leadership Teams.

Perstorp participates in University fairs and supports students in writing their theses.

For three years, Perstorp will be one of six companies working to end hunger in Mem-Chefre in eastern Ghana. The Hunger Project is a global, non-profit, strategic organization committed to the sustainable end of world hunger. Their vision is a world where every woman, man and child leads a healthy, fulfilling life of self-reliance and dignity. Their mission is to end hunger and poverty by pioneering sustainable, grassroots, women-centered strategies and advocating for their widespread adoption in countries throughout the world.

The Perstorp Gymnasium trains and educates 16 to 18 year-olds, and equips them for a technical, vocational career. Our education is divided into two major programs; Industrial Technicians and Electrical & Automation Technicians. During their education, students spend 15 weeks practicing in industry. Many of the students continue working in the company after their exams while some move on to University studies.

At Perstorp, we poured significant energy during 2017 into evolving and strengthening our core purpose, vision and values as a company, and incorporating those into concrete initiatives. It’s a transformation that is tying our heart and soul tighter with our strategy and our outside-in perspective in order to reveal untapped potential for ourselves and our customers. In particular, our core values of Responsibility, Reliability and Focused Innovation are more tightly woven into everything we do as we seek to lead change towards chemistry that advances everyday life for the better. Simply put, at Perstorp we believe in doing right. We believe in keeping our promise. And we believe if it matters, make it better.

We know there is a growth-driving correlation between hard financial performance and softer values. It is that magic formula of performance and caring we are after as we look to build an even stronger culture. Beyond hard numbers, we have created new targets for our caring culture, with a strong focus on leadership and how we support people in an ever changing and challenging environment while also nurturing cross-functional work. One shining example is our Care 365 program, launched in 2017. Integrating all three of our core values, Care 365 pushes us to look beyond statistics and numbers, getting to the heart of what matters to make it better, do right and keep the promise to put care first. Care 365 is rooted in the knowledge that health and safety are blind to work/life borders. We can’t leave stress, fatigue or injuries behind as we walk out the door at the end of the workday. We are committed to leading change towards a healthy and safe Perstorp every day, 365 days a year. We have created a comprehensive initiative to lift up not only the big things, but also the little things to ensure a little hazard doesn’t become a big problem, and to increase our maturity in terms of we Care. There is a slightly positive trend to be seen with e g 20% fewer accidents and incidents in 2017 compared to the previous year but we still have a lot of work to do. We are devoted to taking all the necessary steps, to paying attention to the little things that matter and to strengthening our culture of true Care.

We spoke with Scott Bader’s CEO, Jean-Claude Pierre about sustainability, and it’s clear this is a subject as close to his heart as it is ours. Scott Bader has entered a transformational journey towards a clear vision. This guides them in the decisions they make and the actions they take. Together, we know we can make a difference.

Sustainability is "simply" about acknowledging that nature, society and business are fully interconnected because they are part of the same system. For businesses to thrive, the first priority is to ensure they preserve the nature we all depend upon to live and to ensure they contribute to developing, thriving societies.

In 2017, we embarked on a major transformational journey by defining our 2036 vision and seven strategic goals to achieve it – balancing ecology, humanity and business needs and aligning with the United Nations Sustainable Development Goals. This now defines everything we do, and we are developing a sustainability balance scorecard to track our progress and provide all our employees at all levels in the organization with the visibility they need to make quicker decisions and contribute to our sustainability objectives.

If we talk about the environmental aspect of sustainability, there is a clear progress of awareness about environmental issues that we face. In markets like Europe and China, we're beginning to see more willingness to consider them and, if not to pay more, at least to explore creative ways to develop "greener" solutions. This looks, unfortunately, far less obvious in the United States.

Let's join forces to create greener solutions, whether it is through more bio-derived raw materials or solutions to create a more circular economy. The issue in front of us is not about which company is going to be better off down the road, but whether or not the human species has a future on this planet. This is the level of urgency we are facing even if – like a frog in slowly heating water – many of us do not seem to fully appreciate what is happening.

I do not think we can easily overcome the domination of the financial worldview, which drives how we operate businesses. So we should, in my mind, come to a point where all the external things we neglect to see as a real cost today are put onto our P&Ls and balance sheets.

To Perstorp Holding AB, corporate identity no. 556667-4205

The Board of Directors is responsible for the statutory sustainability report, and that it has been prepared in accordance with the Annual Accounts Act.

Our examination of the statutory sustainability report has been conducted in accordance with FAR´s auditing standard RevR 12 Auditor´s report on the statutory sustainability report. This means that our examination of the statutory sustainability report is different and substantially less in scope than an audit conducted in accordance with International Standards on Auditing and generally accepted auditing standards in Sweden. We believe that the examination has provided us with sufficient basis for our opinions.

A statutory sustainability report has been prepared.

Malmö, April 18, 2018

PricewaterhouseCoopers AB

Michael Bengtsson

Authorised Public Accountant

Mats Åkerlund

Authorised Public Accountant