Effectively preserving feed processed at high temperature

Effectively preserving feed processed at high temperature with ProSid MI 730

Preservation basics

Propionic acid is without competition the class leading preservative for feed. It has a strong and wide preservation effect on yeast and mold, and it effectively prevents toxin formation. The dosage and cost are reasonable and the low viscosity of propionic acid makes it easy to apply by spraying. However propionic acid is volatile as well as corrosive on both skin and steel. The corrosive properties have been solved by buffering with ammonia. This solution is well known in the industry. The volatile properties have proven harder to handle –a significant amount of the product will evaporate during long term storage. The higher the temperature, the bigger the evaporation and consequently the loss of preservative effect.

The non-volatile mold inhibitor

Some processes in feed production involve very high temperatures. A prime example of this is pelletizing. The loss of preservative during these processes is significant when you use traditional ammonia buffered products or pure propionic acid. By adding a product containing a high percentage of propionic acid glycerol esters the evaporation can be controlled and a high amount of the preservative will remain in the feed. In recent studies as much was proven. ProSid™ MI 730 was compared to ammonia buffered propionic acid in feed processed at high temperatures. ProSid™ MI 730 is a concentrated mix of a major part propionic acid glycerol esters, free propionic acid and a water content of only 10%.

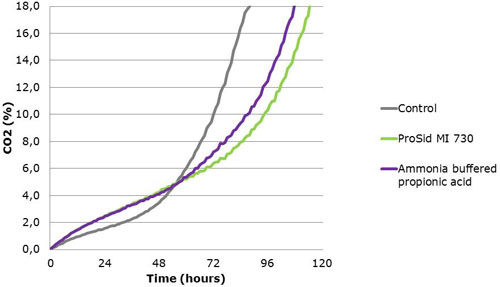

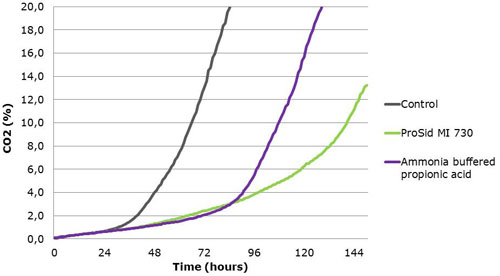

A compound feed was studied in CO2 equipment where one batch was processed at a normal temperature and one batch was processed at an increased temperature. The feed was treated with a conventional ammonia buffered product with benzoate and sorbate or ProSid™ MI 730. Both products contained the same amount of propionates. In the feed processed without high temperature (graph 1) ProSid™ MI 730 performed well with a slightly better effect than the conventional ammonia buffered alternative. In the feed processed with increased temperature (graph 2) the storage period with low microbial activity was double that of the sample which was treated with an ammonia buffered preservative.

Graph 1: preservation of feed at normal temperature. Dosage 1 kg per ton. CO2 production measured in a stress test that simulates practical circumstances. When mold starts to form the CO2 production increases rapidly.

Graph 2: preservation of feed at high temperature. Dosage 1 kg per ton. CO2 production measured in a stress test that simulates practical circumstances. When mold starts to form the CO2 production increases rapidly.

In real life and full scale preservation of pelletized feed, we have had the benefit to see even stronger positive effect using propionic acid glycerol esters. Besides its impressive preservative effect on feed and grains, ProSid™ MI 730 has also shown to possess some beneficial technical properties: the product has also been lauded because of its sticky properties. These help to keep the pellet together and decrease the dust. In short: we believe we have found our champion product for preservation of pelletized feed.